Over the years, melamine has gotten a bad name in the cabinet industry as an option to use for cabinet interiors or even exteriors because of issues relating to water damage, strength, or even general long term durability. The technological advancements in the manufacturing process have significantly increased the quality and durability of melamine. As a result, many of the issues that have existed are no longer such a cause for concern.

The development in recent years of thermally fused melamines has led to many more options, colors, and textures that have become available to use as an option for your cabinets. Some of these melamine panels are directly imitating the character and look of real wood. To the untrained eye, it would be hard to see the difference between a high quality thermally fused melamine door, and an actual wood door. Due to the different issues that melamine has had in the past, some markets have been slower to adopt the new designs and textures that are available. Many people do not understand how melamine advanced as a stable and durable option in the past 5-10 years. Most of the issues that have existed in the past have completed solved.

So what is melamine? On the most basic level, the melamine that Netley Millwork uses is made of 100% recovered and recycled wood materials. These are specifically selected depending on the market and location of the manufacturing plants to create high-quality panels. Some melamine manufacturers will use more hardwood content in their core, and some manufacturers will use more softwood content. From our experience, there is no apparent difference in quality between the two options.

The recycled wood materials are taken together with a proprietary resin formulation and pressed into a raw particleboard panel. All the melamine panels that Netley Millwork uses in our daily production adhere to CARB Phase 2 certification. CARB refers to California Air Resources Board and is a department of the California Environmental Protection Agency. Phase 2 certification refers to the regulation that came into effect in 2010 that mandates that all products that adhere to Phase 2 regulations have formaldehyde emissions at .09 ppm or lower. This is considered the industry standard in North America, however, with the influx of cheap import melamine, many of which do not adhere properly to the Carb Phase 2 regulations.

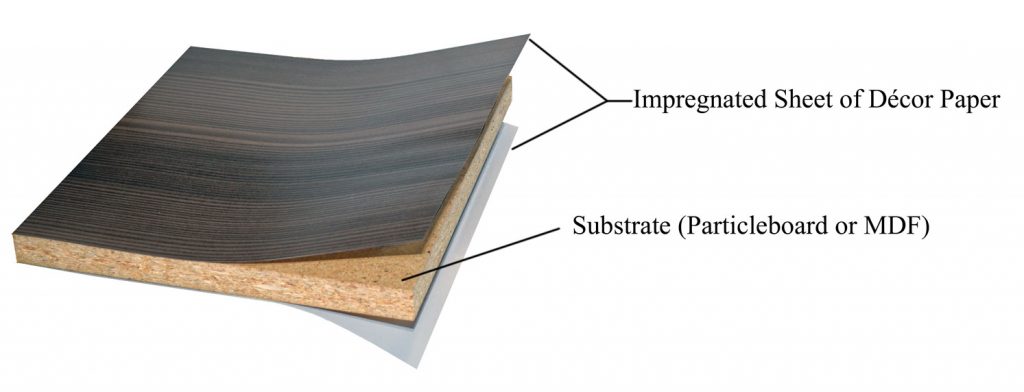

After the particleboard panel has been pressed together, a melamine paper is taken and thermally fused onto the particleboard. This process has been automated to the point where most high-quality melamine panels available on the market have a strict thickness and quality standards that they consistently meet. In recent years many new textures and styles have become available that imitate the look and feel of real wood at a much lower price point. Some of the issues with melamine still exist; however, by taking proper care of your cabinets, most problems can be avoided.

The high-quality melamine that Netley Millwork uses in all our products has superior strength and durability. While not exactly waterproof, the recent addition of new technology that allows us to take advantage of PUR glue, considered a highly water-resistant edgebanding glue. Our melamine panels now have more water resistance than melamine panels with standard EVA edgebanding glue that many manufacturers still use. This can be tested by taking a panel that is appropriately glued using PUR glue and placing it into a tank of water. Even after a week of full exposure to the water, a properly edge banded panel will show no signs of swelling or water damage.

Our standard interior melamine options also offer superior screw holding strength and maintain a highly consistent moisture content that helps keep your cabinets from warping after they have been installed. The other issue is how easily melamine can chip. Excessive chipping will happen because of improper tooling or low-quality equipment being used during the manufacturing of your cabinets. The development of diamond tooling for cutting and edgebanding helps mitigate many of these issues.

To summarize, many of the issues that have existed with melamine cabinets in the past can be avoided if the cabinets are built with proper equipment and resources. That is why it is essential to work with a cabinet manufacturer that has the proper tools, equipment, and resources to help you avoid those problems. Contact us today to start talking about your dream kitchen!